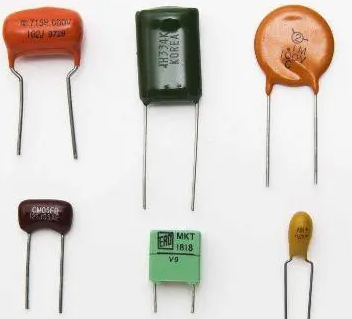

Safety capacitors are an important safety element in electronic products. The main role is to ensure that even if the capacitor fails, it will not endanger personal safety. Given its key role in electronic products, it is particularly important to accurately detect the quality of security capacitors. The following are the specific methods and precautions for detecting the quality of capacitance.

For the test of fixed security capacitors, you can follow the steps below:

1. Detect small capacitors below 10pf.

2. Detect whether the fixed security capacitance from 10PF to 0.01 μF has charging phenomena to determine its performance.

For the detection of JEC security container, the steps and precautions are as follows:

1. Because the capacity of electrolytic capacitors is usually much greater than general fixed capacitors, the appropriate range should be selected according to different capacity during measurement. Generally speaking, 1 to 47μF capacitors can be measured with R × 1K gear, while capacitors greater than 47μF can be measured with R × 100 gear.

2. During the test, the universal surface red table is received to the negative electrode, and the black surface pen is received to the positive electrode. When it was first contacted, the multimeter pointer will turn to the right to a larger angle (for the same resistance, the larger the capacitor capacity, the larger the partial turning range), and then gradually turns, and finally stops at a certain position. The resistance value at this time indicates that the forward resistance of the electrolytic capacitance should usually be above hundreds of kΩ. If there is no charging phenomenon in the positive and reverse tests, that is, the acupuncture is not moving, indicating that the capacitance may be damaged; if the measured resistance value is small or zero, it indicates that the capacitor may leak electricity or has been penetrated.

3. For electrolytic capacitors with unclear logo, their positive and negative electrodes can be judged by measuring the leakage resistance. First measure the resistance once at will, record the resistance value, and then the exchange form pen is measured again. A large resistance value in the two measurements indicates the correct connection method, that is, the black surface pen connects the positive pole, and the red table pen connects the negative pole.

For the test of conventional security and capacitance, pay attention to the following points:

1. When gently moving the axis with your hands, you should feel smooth without looseness or stagnation. Try to promote the shaft in all directions and check whether there are loose.

2. While moving the axis, use another hand to touch the outer edge of the film set to check whether there is a loose phenomenon. If the dynamic film is in poor contact with the fixed film, the capacitor should not continue to use it.

3. Use a multimeter R × 10K gear to detect. One hand connecting the meter pens to the motion and fixed padding of the canal container, and the other hand rotates the axis. During the spinning process, if the multimeter pointer occasionally points to zero, it indicates that there is a short circuit point; if there is an infinite number of readings at a certain angle, there may be a leakage phenomenon.

Through the above detailed detection methods, the quality of security capacitors can be effectively determined to ensure the safe and reliable operation of electronic equipment.